Frontier Research Initiative, NICHe, Tohoku University.

Top Page > Research Projects > Extreme Environment Materials Strength

It is indispensable for detecting materials damages and defects in the early stage of fracture to assure the reliability of the materials and/or to replace or repair the materials timely. To establish the reliable methods for the detection, it is very important to find out the dominant factors that deteriorate the characteristics and reliability of materials. The changes of the surface nano- and micro-textures of materials and the local surface deformation of structures in nano-scale are detected by optically to detect the damages and defects. Small surface cracks are detected by applying electromagnetic waves. The methods for measuring the actual load under operation of various equipments are also developed.

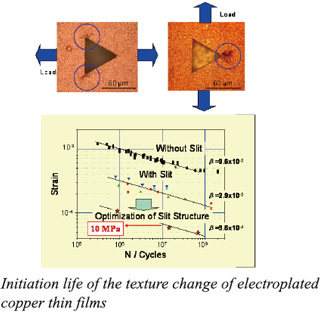

Nondestructive measurement of the amplitude of operating strain at the surfaces of rotating machines

We have been developing a nondestructive strain measurement

method of rotating machines using electroplated copper thin films.

We have been developing a nondestructive strain measurement

method of rotating machines using electroplated copper thin films.

Load amplitude and main load direction can be evaluated

quantitatively by the observation of the change of the surface texture of

copper films.

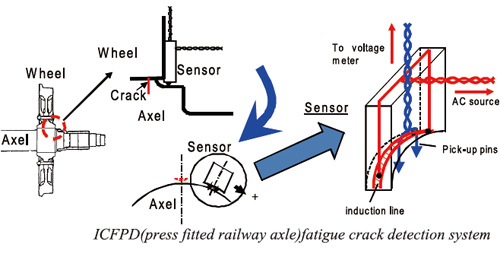

Development of fatigue crack detection in press fitted railway axle by using induced current focusing potential drop technique

In the case of railway axle, fatigue cracks can be generated in press-fitted parts such as wheel seat. To detect this crack , a nondestructive sensor must be located at a point distant from the crack (at least 5mm). Induced current focusing potential drop method (ICFPD method), as one of the potential drop methods, has the potential of detection of such crack. In this study, the ICFPD method using pick-up pin in horizontal direction with respect to crack has applied to detect cracks of wheel seat of railway axle.

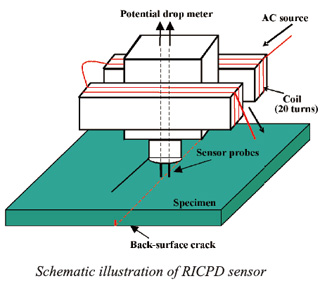

Development of remote Induced current potential drop technique for detecting stress corrosion cracking located inside welded tubes

A highly sensitive and accurate non-destructive evaluation

technique for the detection of defects or cracks inside welded tubes

is being developed. The technique is an improvement of the

conventional Induced Current Focusing Potential Drop (ICFPD)

technique, and is called the Remote Induced Current Potential Drop

(RICPD) technique. In this technique, an alternating electric current

can be induced onto an internal surface, and it is possible to detect

inside surface cracks from the outer surface.

A highly sensitive and accurate non-destructive evaluation

technique for the detection of defects or cracks inside welded tubes

is being developed. The technique is an improvement of the

conventional Induced Current Focusing Potential Drop (ICFPD)

technique, and is called the Remote Induced Current Potential Drop

(RICPD) technique. In this technique, an alternating electric current

can be induced onto an internal surface, and it is possible to detect

inside surface cracks from the outer surface.