Frontier Research Initiative, NICHe, Tohoku University.

Top Page > Research Projects > Extreme Environment Materials Strength

Nuclear power generation is prospected forward to be dominant electricity supplying source in the long term. More reliable and higher key technologies for designing of light water reactors are desired for the nuclear power plant construction. The studies on prospects of the latent phenomena and countermeasure of them are promoting to establish the proactive aging management of the materials for pressurized water reactors (PWR) which is the major nuclear power plant in a world. In particular, the studies on establishing of the proper evaluating and maintaining techniques from the viewpoint of engineering are promoting on the Type 316 austenitic stainless steel, nickel based alloys and their weld metals as the pressure boundary materials of PWRs, and developing of the highly stress corrosion cracking (SCC) resistant materials.

| Local stress measurement at nm level by synchrotron X-ray (SPring-8) | Inter-and intra-granular characteristics at nm level I analyses by high resolution transmission electron microscope | Development of stress corrosion cracking resistant materials by original auto-clave |

|---|---|---|

|

|

|

Fundamental studies to environmental assisted cracking of pressure boundary materials of pressurized water reactors

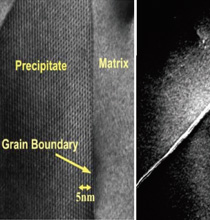

To contribute to the clarifying of the mechanisms and establishing of the countermeasure on SCC of pressure boundary

materials for PWRs, collaborative research programs with Japanese PWR utilities and material supplier on the stress

corrosion cracking initiation and propagation characteristics for the laboratory experiments and actual experiences in

commercial PWR plants. The mechanism of the intergranular stress corrosion cracking (IGSCC) initiation and propagation

for nickel based alloys in high temperature water was studied by the observation and analyses of grain boundaries using

specific tools including the high resolution analytical instruments from the view point of high nano-technology.

To contribute to the clarifying of the mechanisms and establishing of the countermeasure on SCC of pressure boundary

materials for PWRs, collaborative research programs with Japanese PWR utilities and material supplier on the stress

corrosion cracking initiation and propagation characteristics for the laboratory experiments and actual experiences in

commercial PWR plants. The mechanism of the intergranular stress corrosion cracking (IGSCC) initiation and propagation

for nickel based alloys in high temperature water was studied by the observation and analyses of grain boundaries using

specific tools including the high resolution analytical instruments from the view point of high nano-technology.

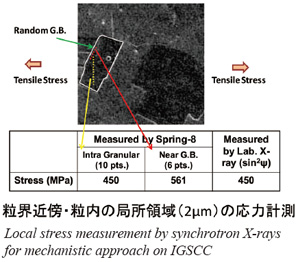

Local stresses near grain boundaries of specimens damaged by SCC were measured with ultra micro beam (<1μm) of the synchrotron (SPring-8) X-ray. It was concluded that the local stress near the grain boundaries affected the IGSCC. The outcome is being applied in controlling stresses for preventing IGSCC. (Cooperative research with University of Hyogo and Japan Atomic Energy Agency)

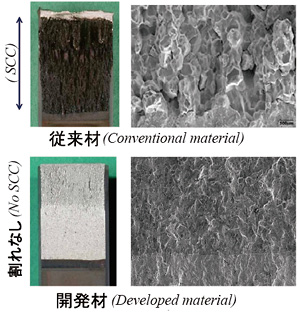

Developing of the stress corrosion cracking highly resistant new materials

Developing the highly SCC resistant and high temperature weld cracking resistant new structural materials that meet to

current material standards are conducting based upon the results of the above essential mechanistic studies and

fundamental scientific principles.

Developing the highly SCC resistant and high temperature weld cracking resistant new structural materials that meet to

current material standards are conducting based upon the results of the above essential mechanistic studies and

fundamental scientific principles.

New super corrosion resistant austenitic stainless steels are developing in application to the structural material, based upon the studies on the effects of chemical compositions on stacking fault energies using high resolutional transmission electron microscope and calculation scientific technique. The material is expected to solve problems specific to the use in the environments with heavy neutron irradiation and / or after fabrication with high degrees of cold work.